ROTARY DAMPER

Specialists in Rotary Dampers for high mobility vehicles since 1995

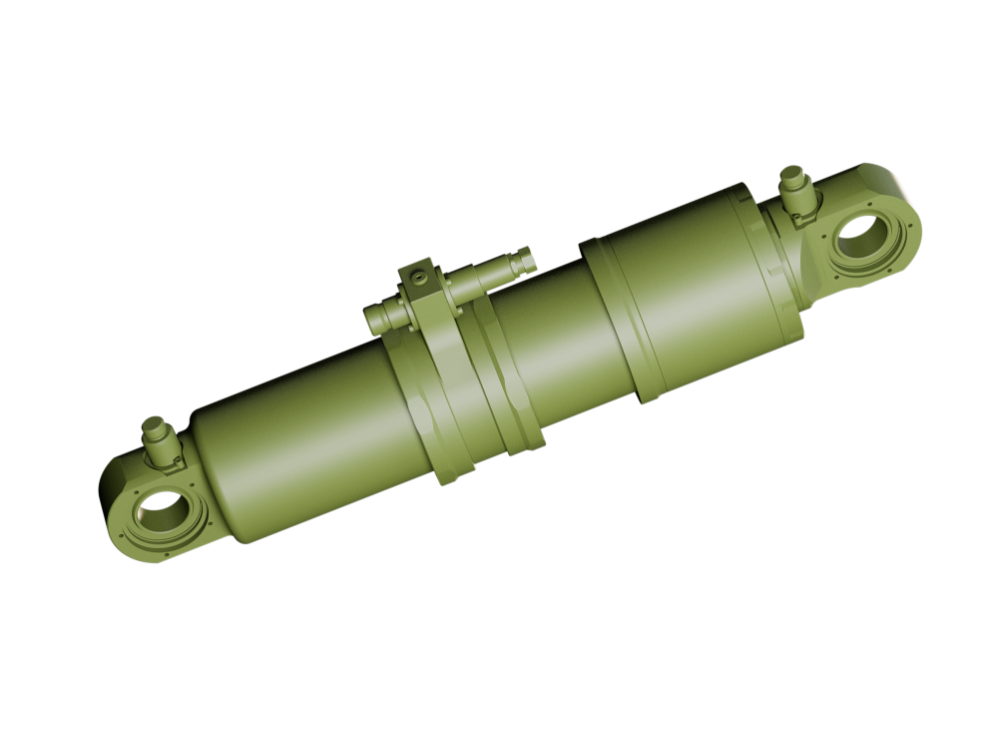

In many applications, rotary dampers are preferred to linear dampers because of their high performance, availability and high energy dissipation capacity.

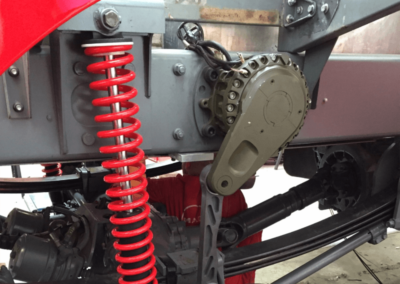

Our rotary damper, as well known as rotary shock absorbers, are specifically designed to improve tracked and wheeled suspension systems.

MAIN FEATURES OF ROTARY DAMPERS:

Great platform stability and comfort

- Due to our full hydraulic characteristic and extreme low friction component which invokes a feeling of comfort inside the vehicle. Tactical platforms are more and more demanded for crew comfort. Rescuing or bringing troops anywhere over the battlefield is requiring the best damping technology.

- Detection tracking and engagement of targets is directly dependant on vehicle behaviour and dynamic. Piedrafita’s proprietary valving system embedded on our rotary shock absorbers results on an improvement of vehicle stability and consequently on weapon and target tracking performance.

- Great response to unexpected obstacles. Our dampers are equipped with ultra-high response pressure limitation system. Resonant dual-pilot blow-off damp control system opening at high angular speed allows to self-protect the damper while maintaining damping force.

Real extreme conditions

- Piedrafita has acquired during more than 3 decades of designing dampers in suspension system an outstanding knowledge in sealing technologies. We learnt from operating conditions and shielded our design against the toughest environments known in the battlefield.

- Our rotay shock absorbers are ready to perform wherever a tactical vehicle can be deployed and a mission must be accomplished.

- Our dampers are mounted behind road wheels and armoured skirt where external agents such as mud, snow or stones become a big deal for most of moving parts.

- Extreme low ambient temperatures is not a problem for these dampers. They are ready to perform at -45⁰C with no impact on the service life of the tank suspension dampener.

25 YEARS Maintenance free

- No oil replacement during lifetime. As our dampers present extreme low friction, there are not wear and fluid is not being contaminated.

- Extreme low friction also implies no sealing replacements.

- Bearing greased for life.

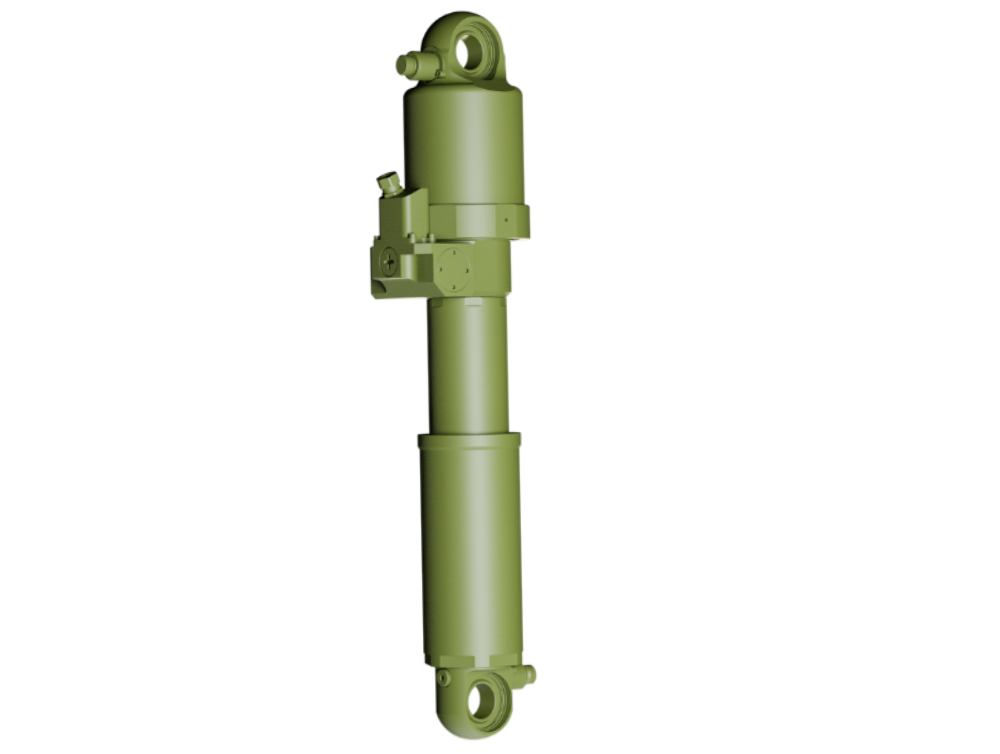

Compact and robust design

- Reduced space claim on wheeled or tracked suspension.

- Excellent ratio volume vs. vertical travel.

- Self-contained compensation chamber.

- No critical surfaces exposed to external threats.

Easy replacement

- “Plug and play” configuration.

- Replaceable with conventional tools.

Ultra-low friction

- Full hydraulic characteristic. Piedrafita’s rotary shock absorbers present less than 40 Nm resistance torque at low rotational speeds; less than the 0.003% of the maximum torque (12,000 Nm).

- No friction elements, no wear of internal parts nor fluid contamination.

- New generation sealing materials coming from state-of-the-art military aerospace technology.

Meeting YOUR damping demand

- Piedrafita’s dampers are fully developed in house. Thus, we are able to adapt our rotary shock absorbers to your application.

- We can modify damping curve by regulating the embedded proprietary systems. This results on the damping curve defined by customer.

Very high working temperature

- Up to 180⁰C continuous, 210⁰C peak, working temperature.

- No temperature effect on damping characteristic. We developed a proprietary valving system embedded in our rotary shock absorbers that assure turbulent flow in the whole working range (-45⁰C to 210⁰C) for disengaging damping behaviour from temperature.

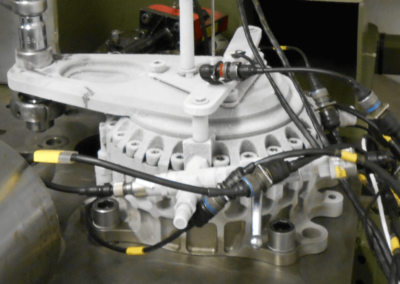

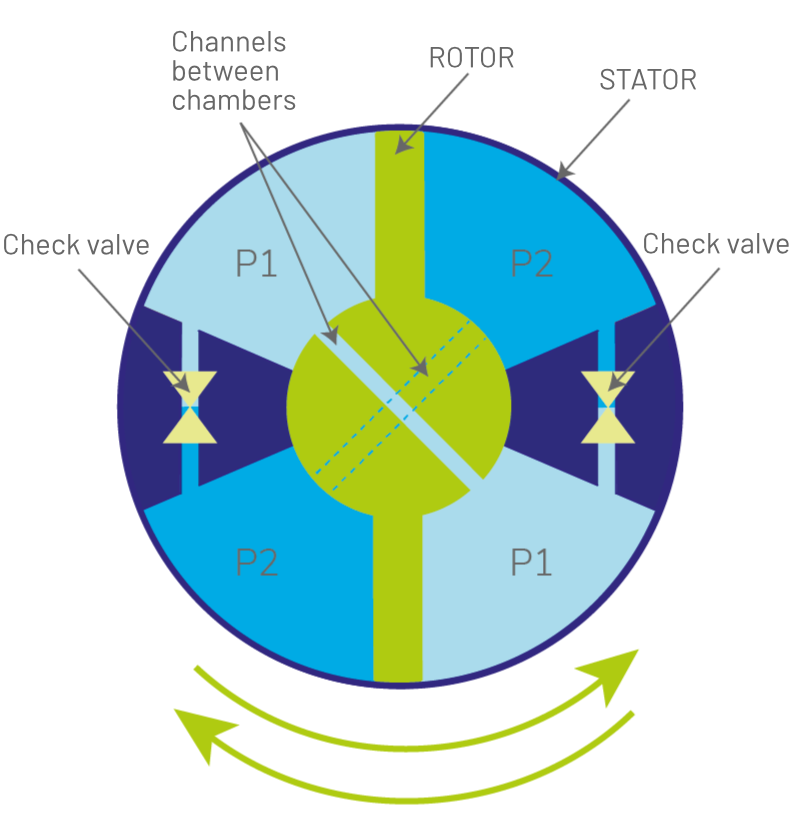

ROTARY HYDRAULIC DAMPER PRINCIPLE

Submitted to a rotational motion input, a rotary damper generates a counter torque to this movement depending on the rotary speed.

The rotor movement generates hydraulic pressure in the High-Pressure chamber (P1 in CCW and P2 in CW). It results a counter force on the inner blades of the rotor that goes against the movement.

The system works independently on both clockwise and counterclockwise side (bump & rebound), providing a full customizable damping curve on both sides (symmetric or asymmetric characteristic).

IN BRIEF

- Designed and validated using Piedrafita’s proprietary technology, our dampers offer unrivalled reliability and durability even in demanding conditions.

- Our rotary damper solutions operate with or without torsion bar.

- They are tailored to accommodate a wide range of vehicles, from agile Unmanned Ground Vehicles (UGVs) to robust Main Battle Tanks (MBTs), ensuring exceptional performance and reliability.

- Versatile and efficient damping solution for retrofitting existing vehicles or designing new platforms to meet specific requirements.

APPLICATIONS FOR USE

Especially designed to withstand the toughest environments, our rotary dampers are the perfect fit for heavy vehicles subject to extreme conditions in the following industries:

- Defence: wheeled or tracked vehicles using torsion bar suspension or not.

- Motorsport: heavy duty dampers for vehicles that take part in racing championships.

- Space: landing leg system for reusable launchers.