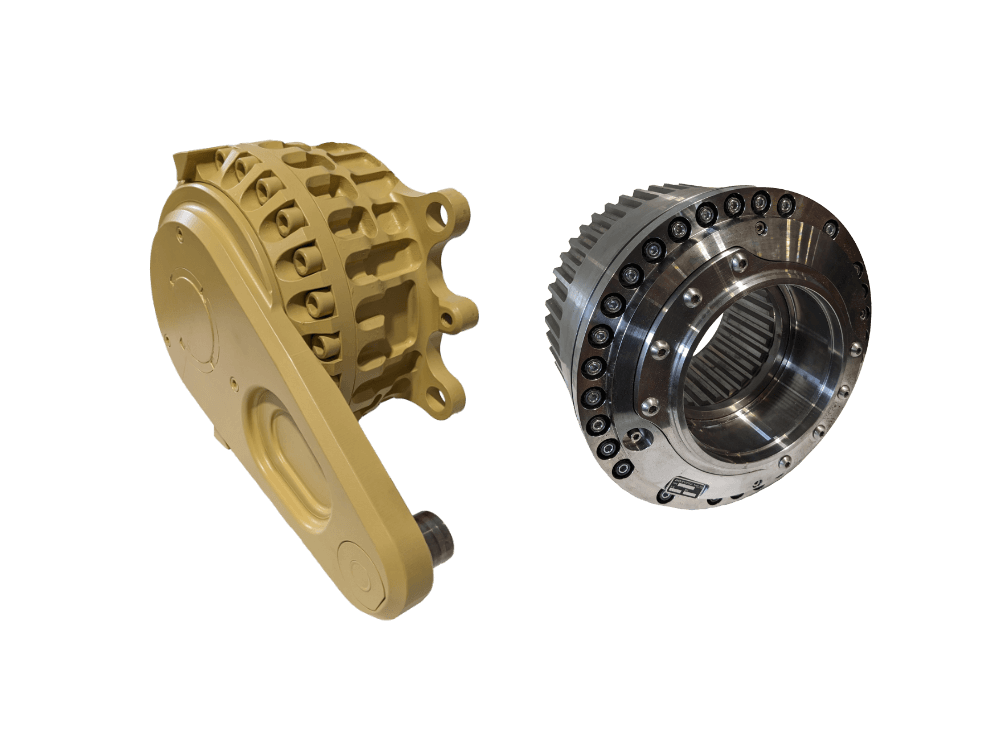

ROTARY SUSPENSION

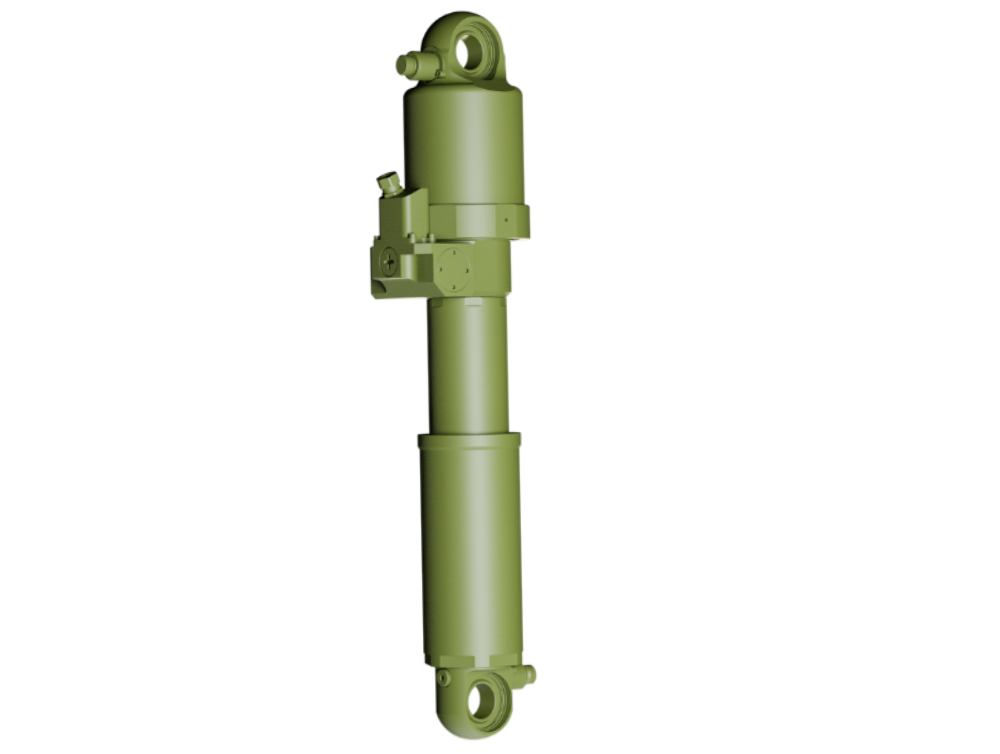

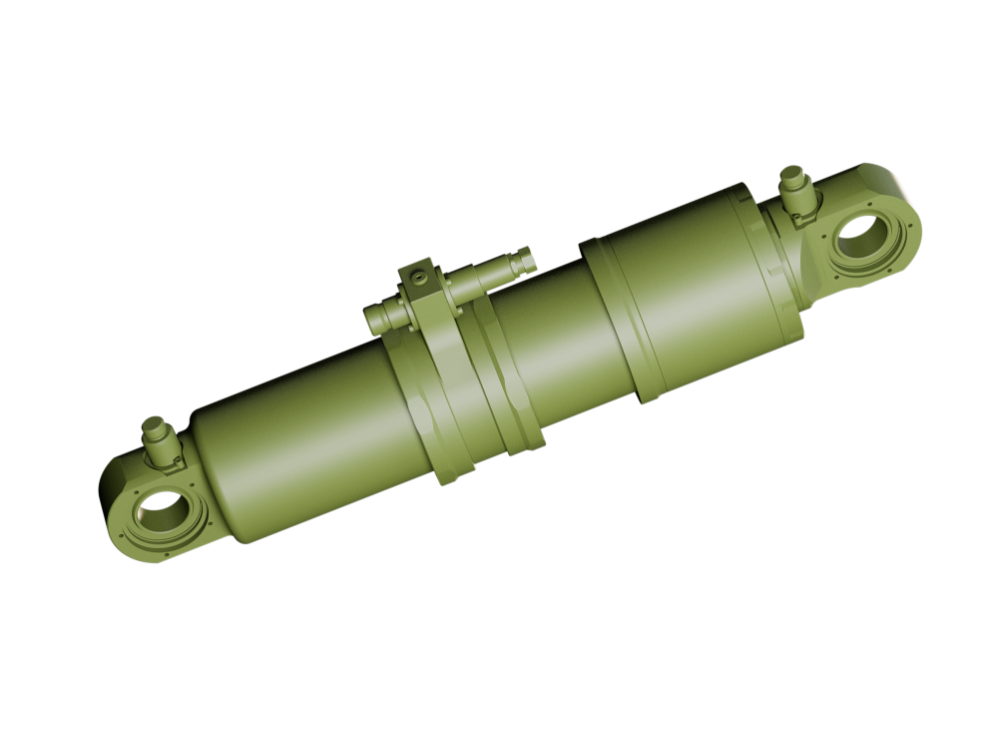

Hydropneumatic suspension integrates both the elastic element and the damped element.

A single system integrating both elastic and damping elements will necessarily result in a much more cost-effective solution than those currently available on the market, as the parts will be greatly reduced and therefore so will the production costs, as well as the design costs, given the greater ease of integration.

Their energy dissipation capability by moving from friction-based technologies to highly efficient and low-maintenance fully hydraulic rotary dampers is the breakthrough that armoured vehicles need to optimize their performance.

MAIN FEATURES OF ROTARY SUSPENSION

This high-performance solution is particularly fit for tracked vehicles due to its compactness, robustness and incomparable energy dissipated/space claim ratio. In the past decades, the constant increase in weight and exigent high -mobility requirements have been challenging the different suspension technologies.

Competitive advantages, both in terms of defence capabilities and in terms of economic competitiveness, include:

Greater mobility as a result of longer suspension travel

Our rotary suspension system provides increased suspension travel, as well as a energy degradation capacity and ride height control, all of which would greatly influence platform mobility.

Energy degradation capacity and ride height control, all of which would greatly influence platform mobility. The suspension system’s energy degradation capacity shall be independent of the suspension travel and position and the proposed solution shall enable a controlled progressiveness throughout the travel.

The energy degrading component shall be a fully hydraulic element, enabling much greater vibration damping, specially at the track patter, thus increasing comfort and aiming capabilities by providing a more stable ride.

Decreased maintenance and increased availability

By employing rotary technology as opposed to friction technology, our rotary suspension eliminates wear elements, and thus reduce the need for maintenance.

It’s a maintenance-free system, guaranteeing that no maintenance shall be required throughout the system’s entire lifetime (estimated at 10-20 years). This effectively nullifies maintenance costs for the vehicle’s suspension and provides a considerable increase in availability.

Increased protection by eliminating torsion bars

By combining the elastic and energy degrading elements into a single product, the suspension system enables the elimination of torsion bars. The use of torsion bars highly affects protection, causing platforms to be more vulnerable to IEDs and mines, thus eliminating them would automatically lead to a better protection.

The addition of a variable ride height enables an even greater improvement in performance against said threats as welI as increased aiming capabilities (by enabling the different suspension systems in the vehicle to be regulated independently from one another).

Easier integrability

Since the use of the torsion bar is not required on armed vehicles using our rotary suspension system, the integration of the system into the vehicle is optimised, making this integration easier.

Directly related to this is the optimisation of time and costs in case of replaceability and repairs, which are much easier than in the case of torsion bar suspension.

Consistent characteristics regardless of temperature changes, thanks to triple valving technology

Piedrafita’s proprietary triple valving technology elevates linear damper suspensions to new heights, offering precise control and reliability. With characteristics unaffected by temperature fluctuations, controlled damper degeneration at high temperatures, and simplified maintenance requirements, this innovative technology ensures optimal performance in high-mobility demanding situations.

Compatible with Heigh Control Systems

Our rotary damper suspension is engineered to seamlessly integrate with Piedrafita’s Digital Suspension Controllers, ensuring compatibility with data acquisition, monitoring, and diagnostic systems for the vehicle suspension as well as the ability of control the heigh of the suspension.

Its plug-and-play functionality simplifies the connection process, allowing for effortless integration and enhanced performance monitoring.

Other remarkable Features

- Low friction torque

- Wide range of operating temperature

- High frequency response

- Self – protected

- Self – contained

IN BRIEF

- Innovative design that integrates elastic and damping elements into a single complete hydropneumatic rotary suspension, resulting in a rotary suspension cost-effective system, that ensures optimal performance.

- The system’s energy dissipation capability and longer suspension travel improve vehicle mobility and stability, particularly in high-demand situations offering higher mobility when compared to conventional suspension solutions.

- Piedrafita’s triple valving technology ensures consistent performance regardless of temperature changes, reducing maintenance needs and increasing system availability.

- Lack of maintenance due to:

- Absence of friction elements

- Optimum sealing

- Absence of elements susceptible to fatigue (mechanical springs)

- The removal of the torsion bar makes its integration or replacement on the vehicle easier and less costly in terms of vehicle availability and economy, as well as providing greater mobility and protection.

APPLICATIONS FOR USE

This hydropneumatics suspension system is particularly suitable for tracked vehicles due to its compact size, robustness and unmatched power dissipation to space claim ratio.

Our rotary suspension solution has been designed to fit a range of existing battle tanks without significant modification. Major MBTs such as Abrams, Leopard 2, Merkal and Leclerc, among others, are able to utilise this cutting-edge technology for unparalleled mobility in challenging conditions.