DIGITAL SUSPENSION CONTROLLER

The purpose of the Digital Suspension Controller (DSC) is to manage a suspension system by:

- Logging and analysing data from both the vehicle and the different suspension components in order to actuate on the different suspension systems and optimize the performance and lifetime of the components.

- Providing value-added data to determine the health and usage of the suspension system and thus enable improved maintenance decision-making by different stakeholders.

- external sensors mounted on suspension elements

- external sensors mounted on other elements, such as damper pressure, height regulation system, damper temperature, etc.

- any data from vehicle data bus: vehicle speed, engine speed, GPS data, throttle position, steering wheel position, etc.

All data collected from sensors or data buses will be aggregated in a unique location, in order to be used for suspension control and actuation.

It can also send information to crew displays.

The Digital Suspension Controller can be integrated with a HUMS (Health Usage Monitoring System) in any type of suspension system (provided by Piedrafita or not) with electronic control or not.

MAIN FEATURES OF DIGITAL SUSPENSION CONTROLLER

Data Sources

- Vehicle ECUs and displays:

-

- Vehicle speed

- Engine speed

- Steering wheel/yoke position

- Throttle position o GPS data

- Tyre Pressure Management System (TPMS) / Central Tyre Inflation System (CTIS)

- ABS

- Suspension sensors (*):

-

- Suspension position

- Damper pressure

- Ride Height Regulation System (RHRS)

- Damper pilot valve position

- Damper temperature

(*) The subsystems sensorization level will depend on the selected layout

Data processing and algorithms creation

Algorithms are used to process the input data to make the appropriate actuations.

Algorithms can be deployed in the DSC by stakeholders related to the vehicle’s life cycle as:

- Vehicle manufacturer

- Subsystems manufacturers

- Maintenance centres

- End user

Algorithms privacy

The DSC is a system that allows every stakeholder to create their own algorithms with implemented privacy protocols. Algorithms are stored in the DSC as DLL files. These files are protected, and they cannot therefore be accessed by other stakeholders.

Advantages of raw data in real time

The DSC can process raw data in real time offering the following advantages:

- Reduced Latency: The insights of the data processing are available directly in the vehicle without having to be sent to any central server.

- Improved Suspension Reliability: The vehicle tribulation can make on-road decisions to prevent a system failure.

- Increased Security: The DSC processes data locally, reducing the risk of data interception and compromise.

- Improved Data Storage: Since the algorithms are providing postprocessed valuable data, it is not necessary to store raw data.

Suspension Data Management

To optimize decision-making regarding suspension maintenance, DSC can generate postprocessed data in order to:

- Provide valuable insights into the current state of the suspension systems.

- Help users to identify and prioritize maintenance tasks, ensuring that resources are used efficiently, and the suspension systems remain in optimal condition.

- Help to identify patterns and trends that may indicate broader issues, allowing for proactive maintenance

-

Components Traceability

The DSC processes identifiers such as components serial numbers and part numbers and the dates in which these components have been replaced or repaired, combining this information with sensors data and bus data to deploy insights sorted by serial number. For example, component mileage by S/N.

There are two operating modes according to the methods in which the components serial numbers are stored:

- Standalone: In this mode, the operator will manually introduce the data about the components serial numbers and replacements.

- Connected to a traceability system: The DSC will be connected to any stakeholder tool such us Piedrafita’s Automatic Traceability System, called SICVE. This tool allows the stakeholder to trace the items by using digital techniques like NFC, RFiD or artificial intelligence image recognition (used for license plates, identification numbers, tags numbers, etc)

IN BRIEF

The Digital Suspension Controller (DSC) optimises suspension performance and longevity through:

- Comprehensive Data Analysis: It logs and analyses vehicle and suspension component data to enhance system performance and lifespan.

- Integration Capabilities: Compatible with various external sensors and vehicle data buses, consolidating all information for precise suspension control.

- Stakeholders can deploy tailored algorithms, enhancing vehicle maintenance and performance across the lifecycle.

- Real-time Data Processing offers reduced latency and increased security by locally processing raw data, improving decision-making and reliability.

- Generates post-processed data for insightful maintenance decisions, prioritising tasks and ensuring optimal suspension performance; which offers comprehensive and advanced suspension management.

APPLICATIONS FOR USE

Terrain detector

One of the main applications for use in special vehicles is evaluating the type of terrain on which the vehicle is driving.

The terrain detection is carried out using an algorithm that identifies the terrain on which the vehicle is running. A second algorithm defines the suspension automatic setup depending on the terrain detected.

Our Digital Suspension Controller system is able to optimize the suspension performance by adapting the suspension setup to the type of terrain detected: on-road, off-road, cross-country, sand,…

Suspension Digitaliser

Our DSC is able to infer which is the best suspension setup to use for a particular vehicle by analysing different inputs, such as:

- type of terrain detected

- vehicle speed (via vehicle bus)

- steering wheel position (via vehicle bus)

- dampers temperature (via sensors input)

- Driver mode switch (via vehicle bus)

- DSC Accelerometers and Gyroscopes (integrated in the DSC)

The result is suspension that is fully optimised to the unique and exclusive needs of the vehicle and the driving situation.

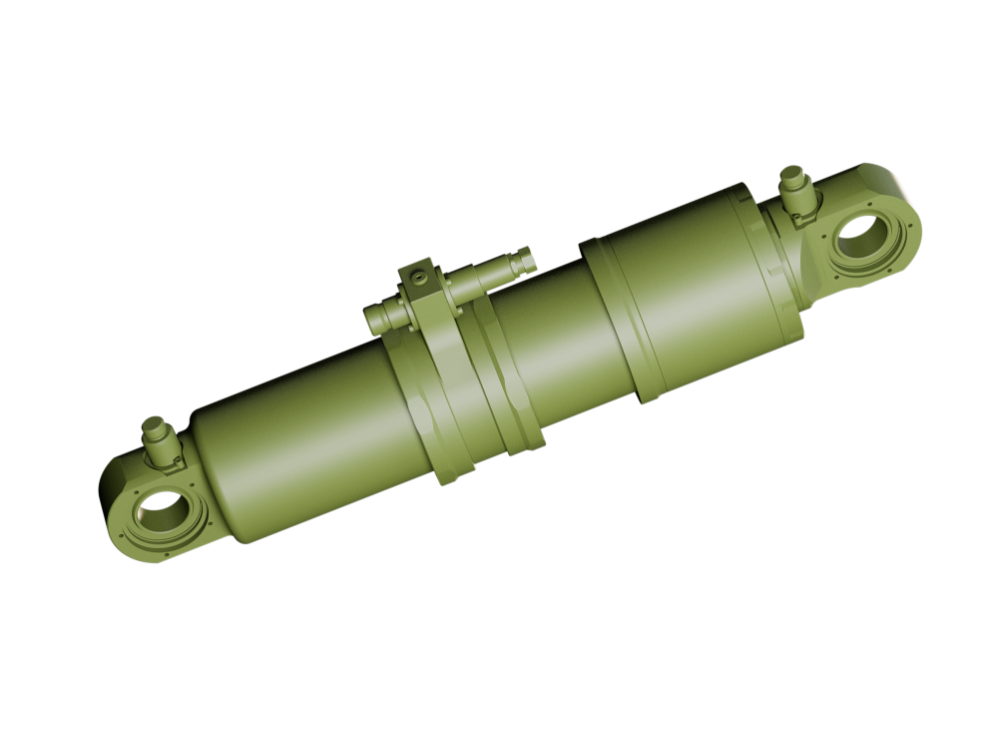

Height Control System

Height control is a must when it concerns greater mobility and confidence in the vehicle, while at the same time enhancing the comfort of the vehicle occupants. With our DSC it is possible to have automatic height control without relying on human criteria.

Using data acquired from the sensors, and with programming based on algorithms, the Digital Suspension Controller is able to determine the optimal suspension height, depending on the type of terrain detected and vehicle dynamics.

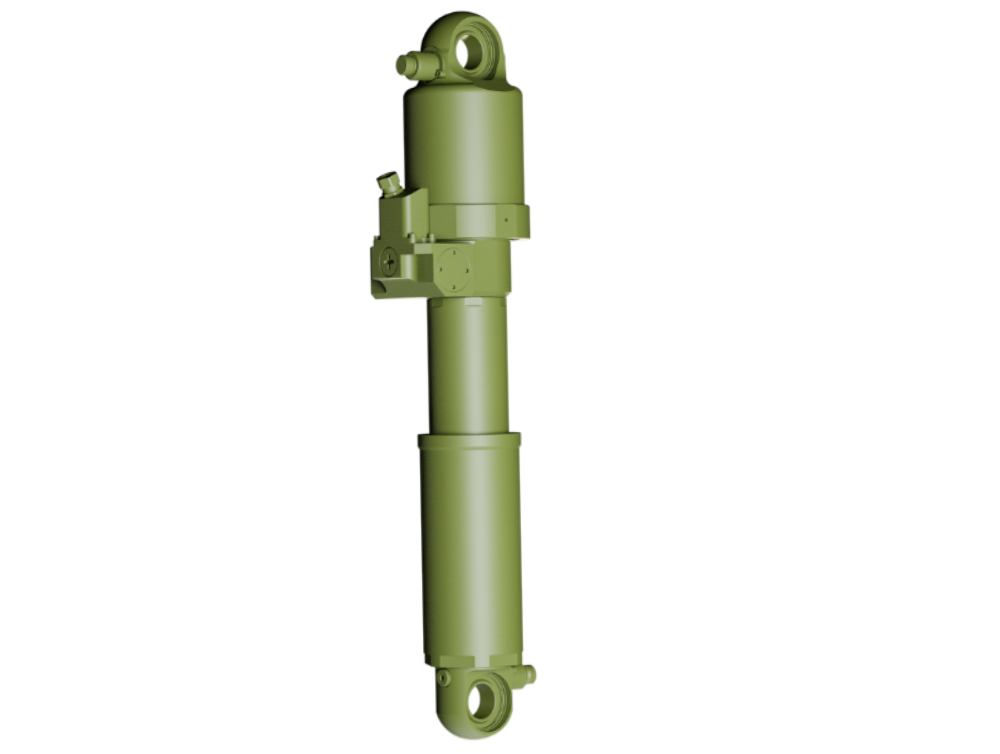

Active Track Tensioning

Our DSC features a configuration that, using different algorithms, is capable of automatically managing the track tensioning according to the type of terrain detected. Depending on this recognition, the track chain tensioner distributes the stress, preventing the breakage of the track and other components from being affected.

SICVE - Components Traceability

The fleet management system is a necessary resource when it comes to optimising the availability of vehicles that can be used in a specific mission. It minimises the time that platforms are under maintenance, and prevents vehicles that do not need to be repaired from being sent to the workshop.

The system allows recording the physical parameters to which each vehicle and, therefore, its components are subjected. This provides valuable information, giving an insight into the actual usage of the vehicles and their components.

Our fleet management system is able to generate automated reports that combine traceability and identification information with immediate notifications and warnings, both for vehicles, systems, components and users.