HYDROPNEUMATIC TRACK TENSIONER

In tracked vehicles, the correct track tension is a crucial factor to ensure optimum performance.

The right tension directly influences the vehicle’s handling, fuel consumption, the comfort and safety of the crew and the lifespan of the tracks.

This is where the track tensioner comes into play, an essential part that works in conjunction with the tracked suspension system to keep the track at its ideal tension point.

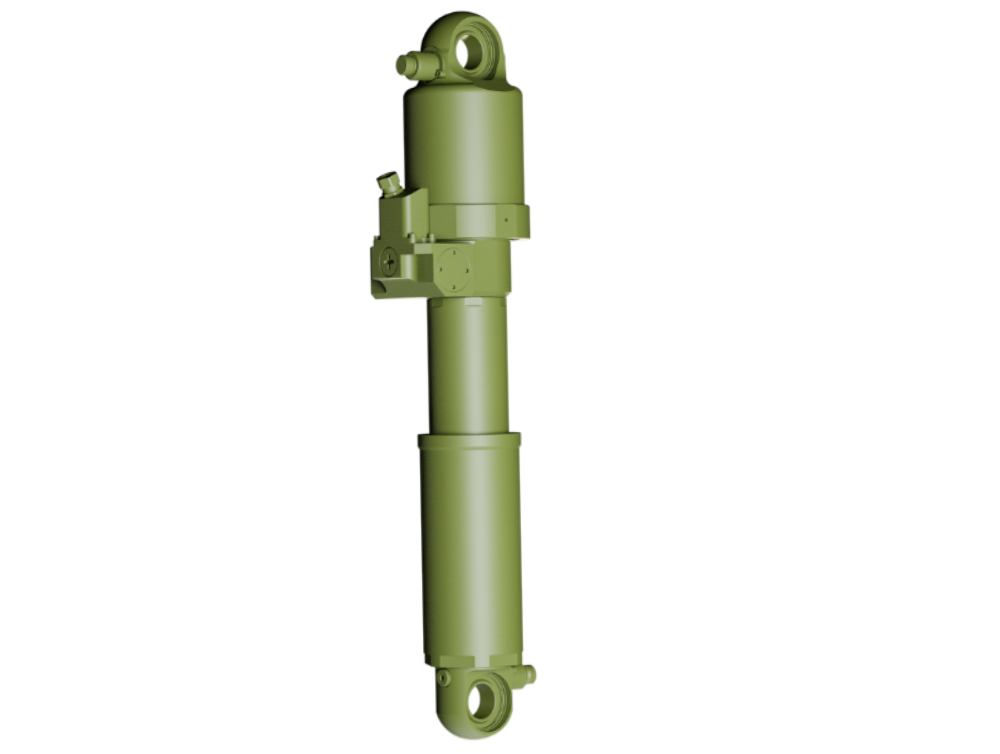

The track tensioner is installed on the vehicle’s barge and operates on a idler wheel. This wheel can pivot to increase or decrease the effective length of the track, thus adjusting its tension due to the elasticity of the track. The tension is adjusted by the track tensioner, which is extended or compressed from an initial operating point.

MAIN FEATURES OF OUR TRACK TENSIONER

High capacity of compression and extension

- Compression (Collapse Travel): Minimum 80 mm.

- Extension (Rebound Travel): 30-60 mm.

- The track tension can be adjusted according to operational needs.

Adjustability thanks to its gas preload

- Nominal Tension Point Adjustment Travel: Adjustable according to the gas preload.

- Maximum Force: 300 kN (adjustable according to gas preload).

- Customisation according to vehicle specifications and operating conditions.

Wide operating temperature range

- Effective operation in temperatures from -46ºC to 120ºC.

- Ideal for various climatic conditions and demanding operating environments.

Optimized dimensions and weight

- Main dimensions in nominal position: 750 x 155 x 250 mm.

- Weight: 30 kg.

- Compact and lightweight design, suitable for a wide range of track vehicles.

Benefits of a high quality Track Tensioner

- Improved Mobility: A properly tensioned track allows for more precise control of the vehicle, improving its mobility.

- Increased Lifetime: Keeping the track at the proper tension reduces wear, resulting in longer life for the track and other components of the system.

- Energy Efficiency: Optimal track tension reduces fuel consumption, resulting in more economical operation.

How the track tensioner works

- Initial Starting Position: The initial position of the tensioner is adjusted by inserting or removing oil or grease through the oil port.

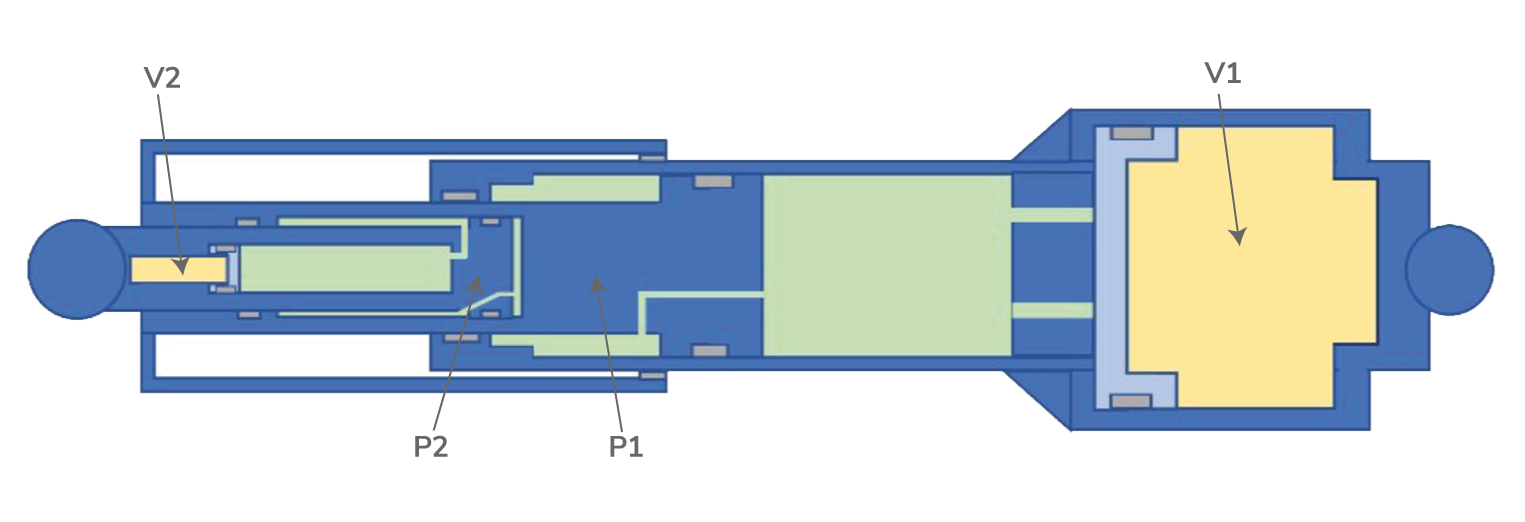

- Collapse Travel: The main piston (P1) compresses the volume of Nitrogen (V1), increasing the force applied to the track to keep it taut.

- Rebound Travel: The secondary piston (P2) extends if the track loses tension, accompanying this movement while continuing to apply the force necessary to hold the track in place.

IN BRIEF

- Our track tensioners are fully adjustable, allowing you to customise the gas preload and compression force to suit your vehicle’s specific needs.

- Designed to operate in a wide range of temperatures, our track tensioners are ideal for all climates and operating conditions.

- Our track tensioners not only regulate the tension of the track, but also work in conjunction with the vehicle’s suspension system. This ensures that the tension remains constant even in harsh terrain and demanding operating conditions.

APPLICATIONS FOR USE

The track tensioner developed by Piedrafita is specially designed and optimized for use with suspension systems in tracked vehicles weighing up to 70 tonnes. This advanced track tensioner is suitable for both new vehicles and the retrofitting of legacy vehicles, ensuring enhanced performance and longevity. Ideal for demanding operational environments, Piedrafita’s track tensioner offers robust, adjustable, and reliable tension management, making it the perfect choice for modern and updated tracked vehicles.